Start your digital transformation

Quantum is here to meet the needs of companies to innovate, to make room for Industry 4.0 and to emerge victorious and profitable.

It is the perfect tool to ride the wave of digital transformation together with the best technologies in the field of Artificial Intelligence, Internet of Things, Machine Learning, Deep Learning and Big Data.

Production in your pocket

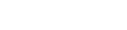

Data in real time

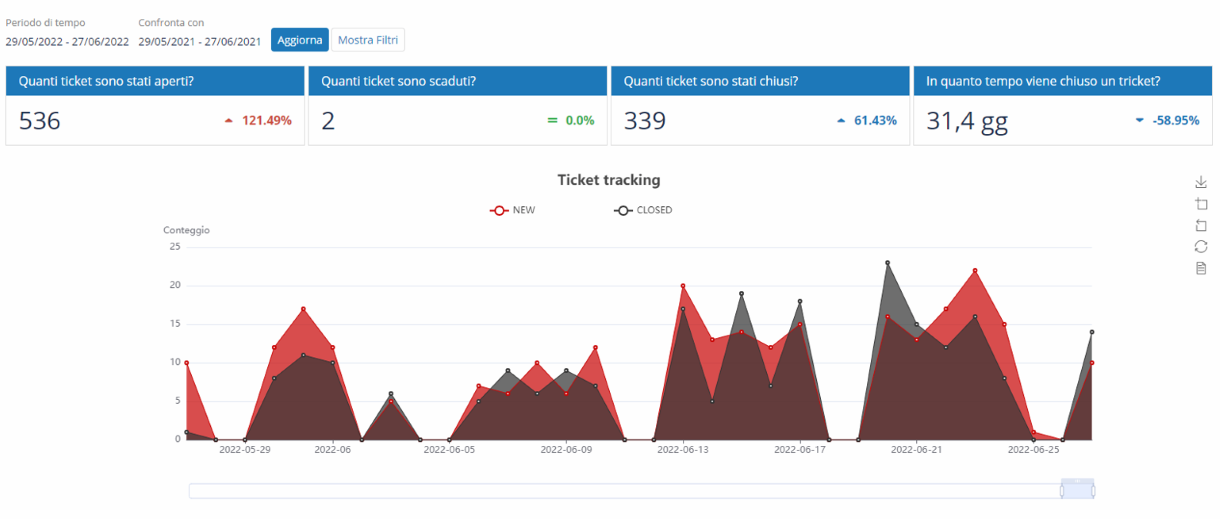

Real-time monitoring of all machines. From those in production to those already delivered to your customers

From past to future

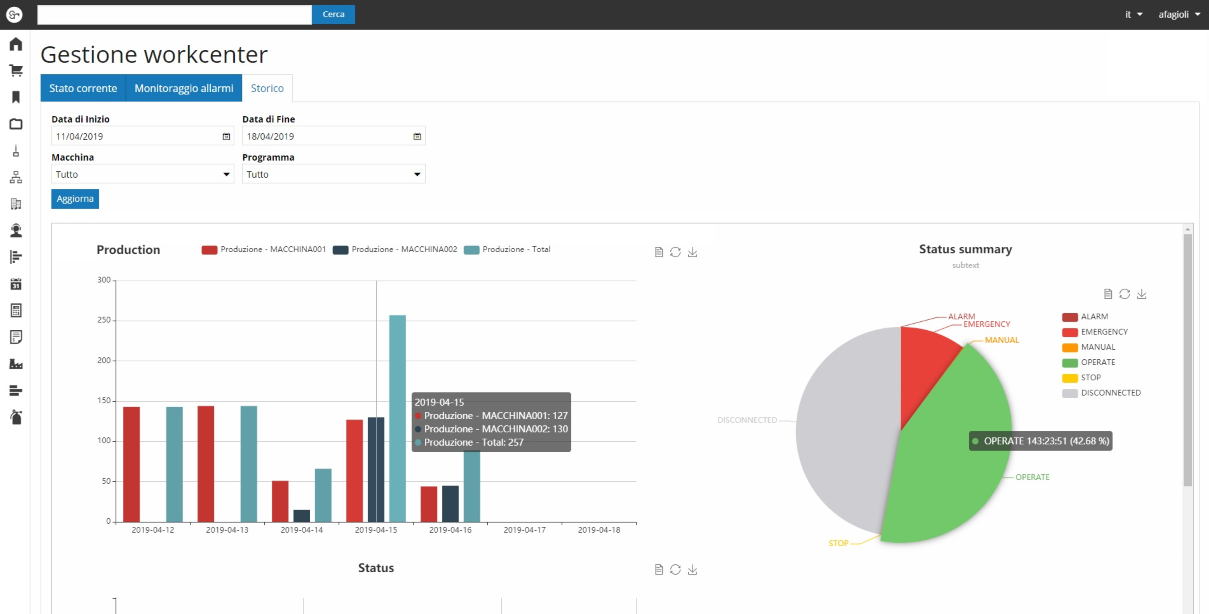

Data from the IoT is correlated with data already on your SolidRules Desk. Thanks to its Business Intelligence tools analyzes all the information to bring out critical issues and opportunities

Autonomy has a value

A 4.0 factory management system capable of working with the Internet and without the Internet, with data in cloud or with data in your premises and without the need to rely on third-party services. You can be in complete control of your information

An Artificial intelligence…naturally intelligent

The market already offers many IoT solutions, this is undeniable, but these are almost always Internet of Things solutions that work by exploiting mostly third-party cloud services.

To overcome all this, we thought of a completely self-sustaining solution that doesn’t need any external services to work, which you can install directly into your infrastructure in an approach that can be Intranet of Things.

Let your machines talk

If your work center is connected to the network and you have SolidRules Quantum iot then the Start and End of work processes could come directly from the machine without even the need for an explicit statement from the user.

At the end of processing you can immediately make the required checks, report anomalies or provide suggestions for continuous improvement.

The production manager will always know the production situation and can reorganise it according to priorities.

Predict and avoid production shutdown

The worst nightmare of every company is the block of production, the "machine stop". This leads to a loss of productivity and consequent economic damage.

This is why "predictive maintenance" comes into play where defects can be "anticipated" by employing automated preventive measures.

Thanks to a system that collects data from machines, interventions, spare parts and service and allows you to implement predictive maintenance.

This allows the management of signals even when they come automatically from the machine.

Big Data

The experience made on the SolidRules Desk in managing millions of documents was transferred to SolidRules Quantum where we simply went from millions to billions. A factory has so many machines, each machine has different sensors, each sensor provides hundreds of measurements every minute.

SolidRules Quantum stores individual surveys and analyses them to extrapolate the KPIs (performance indices) that best suit your business. If you decide to change the parameters of the analysis there is no problem because, starting from the raw data, you have the chance to bring out more objectives.

Machine Learning e Deep Learning

SolidRules uses an Artificial Intelligence system based on Machine Learning and Deep Learning. This system can analyse data and learn from them and then make autonomous decisions based on experience, thus not requiring programming in advance all the situations.

Energetic efficiency

In addition to control everything related to your production SolidRules Quantum can also supervise your buildings.

To cope with energy costs, you can make your building smart and able to self-regulate thus reducing unnecessary waste of energy.

Smart buildings are based on two main systems: smart lighting, capable of adjusting light levels based on user data and behaviour, and HVAC (Heating, Ventilation and Air Conditioning) system.

Thanks to these buildings, able to control the energy used, it is possible to reduce energy waste thanks to an indicator that detects when to stop or activate the energy supply in a space.

Quantum of possibilities

- See the trend of the machines in real-time based on measurements

- See the alarm situation with the possibility to open Ticket on SolidRules Desk

- Read machine counters to advance production steps on the SolidRules Desk

- Analyse historical data to bring out critical issues and opportunities thanks to unique Deep Learning tools

- You have a solution that can communicate with your machines inside the factory or with those sold to your customers

- Work according to the Internet of Things model but also as an Intranet of Things to have total control of data, costs and time

Who is made for

Don’t think that SolidRules Quantum is confined only to production because he too has a boundless ambition. For example, it can also become a tool to record how resources interact with the company and with software. You may find that the quality procedure you have developed over months of work is not read by anyone. You can manage an entire building with the Smart Building system.

In addition, SolidRules Quantum combined with SolidRules Desk allows you to automatically control every step of your business.

How far can it go?

The real question is how far can SolidRules Quantum go? This is an answer that we are not able to give. When you develop an Artificial Intelligence system where Machine Learning, Deep Learning and Virtual Reality move from theory to practice, it is not surprising that tomorrow he will be directly answering this question.

Do you want to see some real example?

Download the SolidRules product brochure

Fill out the form and receive the complete catalog with all the information.

Any question? We are here for you.

Fill out the form or send us an email to info@solidrules.com. We will contact you to provide you all the solutions.